Exactly How Plastic Injection Molding Guarantees Uniformity and Accuracy in Manufacturing

Exactly How Plastic Injection Molding Guarantees Uniformity and Accuracy in Manufacturing

Blog Article

Comprehending the Essentials of Plastic Injection Molding Procedures

Plastic injection molding serves as a keystone of contemporary production, supplying a methodical technique to creating complex elements with accuracy. This procedure not just incorporates the essential steps of melting and injecting products into molds yet likewise entails a nuanced understanding of numerous influencing aspects, such as temperature level and stress. As sectors significantly require performance and high quality, the details of this methodology end up being a lot more crucial. Discovering these crucial aspects could reveal how even small modifications can cause considerable enhancements in manufacturing results, increasing questions regarding the capacity for advancement in this established procedure.

What Is Plastic Shot Molding?

Plastic shot molding is a commonly made use of manufacturing procedure that transforms polycarbonate and thermosetting products into exact and complex forms. This strategy is favored for its capacity to produce high quantities of identical get rid of outstanding accuracy, making it a vital method in different sectors, including vehicle, durable goods, and clinical devices.

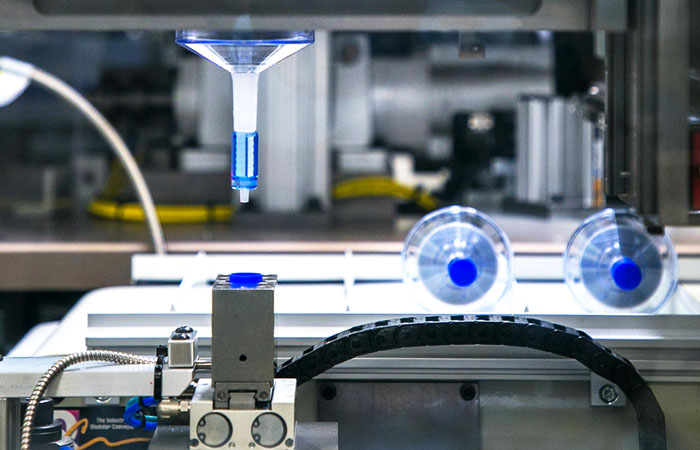

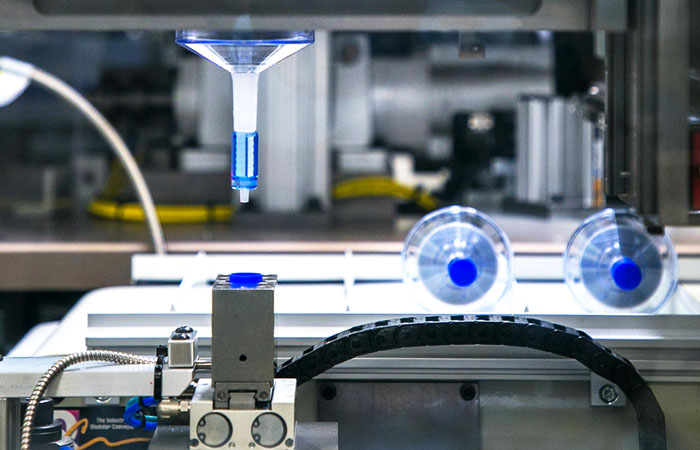

The process includes thawing the selected plastic product and injecting it into a mold and mildew under high stress. The mold and mildew, developed to the specs of the wanted part, allows the molten plastic to take form as it cools down and solidifies. When the product has actually set, the mold and mildew is opened, and the completed component is ejected.

Plastic injection molding provides numerous benefits, consisting of decreased waste, consistency in manufacturing, and the capacity to include intricate designs that may be challenging with other producing techniques. Additionally, it supports a broad variety of materials, each supplying one-of-a-kind residential properties that can be customized for certain applications. As sectors proceed to introduce, plastic shot molding continues to be at the center, making it possible for the growth of innovative items that fulfill progressing customer demands.

The Injection Molding Process

The shot molding procedure is an innovative technique that includes a number of essential stages to produce top quality plastic components. Plastic pellets are fed right into a warmed barrel where they are melted right into a thick fluid. This molten plastic is after that infused under high pressure into a precision-engineered mold, which shapes the product right into the preferred form.

Once the mold and mildew is filled up, the plastic is enabled to solidify and cool, taking the form of the mold cavity. Cooling time is critical, as it influences the cycle time and the final homes of the molded component. After sufficient air conditioning, the mold and mildew opens, and the ended up element is expelled utilizing ejector pins.

Products Utilized in Shot Molding

Various products can be used in the injection molding procedure, each offering one-of-a-kind homes that accommodate particular applications. The most generally used materials include thermoplastics, thermosetting plastics, and elastomers.

Thermosetting plastics, like epoxy and phenolic resins, go through a chemical change throughout the treating process, causing a stiff, stringent structure. These materials are suitable for applications calling for high warm resistance and architectural integrity, frequently made use of in vehicle components and electric insulators.

Elastomers, including silicone and rubber-based materials, provide adaptability and durability. Their one-of-a-kind buildings make them ideal for applications that demand elasticity, such as gaskets and seals.

Furthermore, specialty materials like bio-based plastics and composites are obtaining grip for their ecological benefits and boosted efficiency qualities, expanding the range of shot molding applications in different sectors. Understanding the residential properties of these products is crucial for choosing the suitable type for particular tasks.

Benefits of Injection Molding

Injection molding sticks out as a very reliable production procedure that offers various advantages for producing complex components with accuracy. Among the most significant advantages is the ability to produce elaborate layouts that would be difficult or impossible to accomplish with various Visit This Link other approaches (Plastic Injection Molding). The process permits tight tolerances and detailed attributes, guaranteeing high-quality elements

In addition, injection molding is recognized for its fast production capabilities, making it an excellent option for high-volume manufacturing. As soon as the mold is created, parts can be produced swiftly, minimizing lead times and increasing total performance. This performance not just decreases manufacturing costs however additionally supplies an affordable edge in have a peek here the market.

The versatility of materials made use of in shot molding further boosts its appeal. A wide variety of thermoplastics and thermosetting polymers can be used, permitting makers to select products that ideal satisfy their particular needs, including adaptability, warmth, and toughness resistance.

Moreover, the procedure lessens waste, as excess product can typically be recycled and recycled. This sustainability facet adds to a minimized environmental impact, making shot molding a responsible manufacturing option. Overall, the benefits of injection molding make it a recommended approach for lots of industries.

Variables Influencing Item Top Quality

While various factors can affect item high quality in injection molding, understanding these components is crucial for achieving optimal outcomes. Trick facets include product selection, refining specifications, and mold and mildew style.

Material selection plays a crucial duty, as different polymers exhibit special residential properties that influence flowability, toughness, and thermal security. Poor product option can lead to issues such as warping or insufficient dental filling.

Handling criteria, including temperature level, cycle, and stress time, must be meticulously regulated. Variants in these settings can result in inconsistencies partly measurements and surface finish. As an example, exceedingly high temperatures may create deterioration of the polymer, while inadequate stress can cause short shots.

Mold layout is similarly important, as it determines the circulation of the molten plastic and the cooling process. Inadequately created molds may bring about unequal air conditioning rates, resulting in residual stress and anxieties and dimensional mistakes.

Final Thought

To conclude, plastic shot molding acts as an essential production procedure that makes it possible for the reliable production of top notch parts. Proficiency of the injection molding process, including the understanding of materials and the impact of numerous variables on item top quality, is crucial for attaining optimum outcomes. The advantages of this method, such as cost-effectiveness and layout adaptability, more highlight its importance across multiple sectors, strengthening its condition as a preferred choice for high-volume manufacturing.

Plastic shot molding serves as a cornerstone of modern-day manufacturing, offering a methodical technique to creating complex components with accuracy.Plastic injection molding offers numerous advantages, including minimized waste, consistency in manufacturing, and the capacity to incorporate intricate layouts that might be challenging with various other producing approaches (Plastic Injection Molding). As markets continue to introduce, plastic shot molding continues to be at the leading edge, allowing the advancement of innovative products that meet evolving customer needs

The injection molding procedure is an advanced method that entails a number of essential stages to generate article source top notch plastic components.In verdict, plastic injection molding offers as a vital production process that makes it possible for the effective manufacturing of top quality parts.

Report this page